In the petroleum refining and chemical industries, many media exhibit certain degrees of corrosivity, such as common industrial products like sulfuric acid (H2SO4), alkalis, and ammonia water, which corrode various metallic and non-metallic materials to varying degrees.

Based on the composition, concentration, and temperature of the medium, select corresponding metallic materials and non-metallic seals. Different concentrations and temperatures require the use of different corrosion-resistant materials to ensure compatibility and economic efficiency between the materials and the pipeline medium. In terms of valve selection, gate valves, globe valves, check valves, ball valves, butterfly valves, and others are recommended.

Vibration conditions mainly occur near equipment such as pumps and compressors during oil and gas transportation, or when pipelines traverse complex terrains. Vibration can lead to fatigue damage to pipelines and equipment, accelerating the aging and failure of valves.

When selecting valves, in addition to considering their vibration resistance, it is also necessary to comprehensively select based on specific working conditions (such as media properties, temperature, pressure, etc.) and usage requirements (such as manual operation, electric control, etc.). Options include anti-vibration valves, metal-sealed ball valves, and so on.

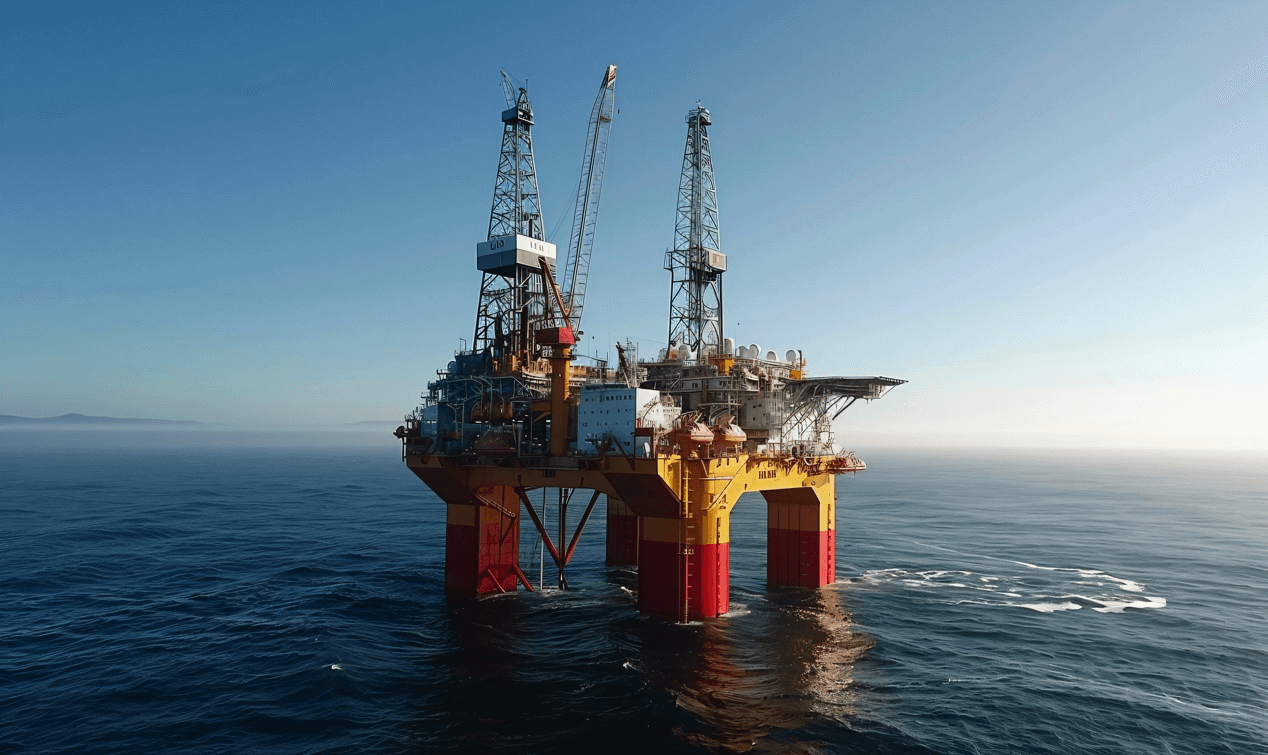

High-voltage conditions are commonly encountered in long-distance oil and gas pipeline transportation, which can enhance the efficiency of oil and gas transportation. However, they also impose stricter requirements on pipeline materials, sealing performance, and safety. In high-pressure environments, valves need to withstand greater stress, thereby increasing the risks of leakage and rupture.

Specially designed ball valve and gate valve manufactured by high voltage resistant material can maintain positive stability and safety under high volatage.

Low-temperature conditions mainly occur in cold regions or during the transportation of liquefied natural gas, which can lead to the embrittlement of pipeline materials, increasing the risk of pipeline rupture. Meanwhile, low temperatures can also affect the media within the pipeline, such as causing the liquefaction of natural gas or the formation of hydrates. High Pressure Operating Condition.

In low-temperature environments, valves need to have good thermal insulation performance and resistance to low-temperature brittleness. Special materials and insulation designs are adopted for low-temperature ball valves, low-temperature gate valves, etc., to meet the operating requirements under low-temperature conditions.

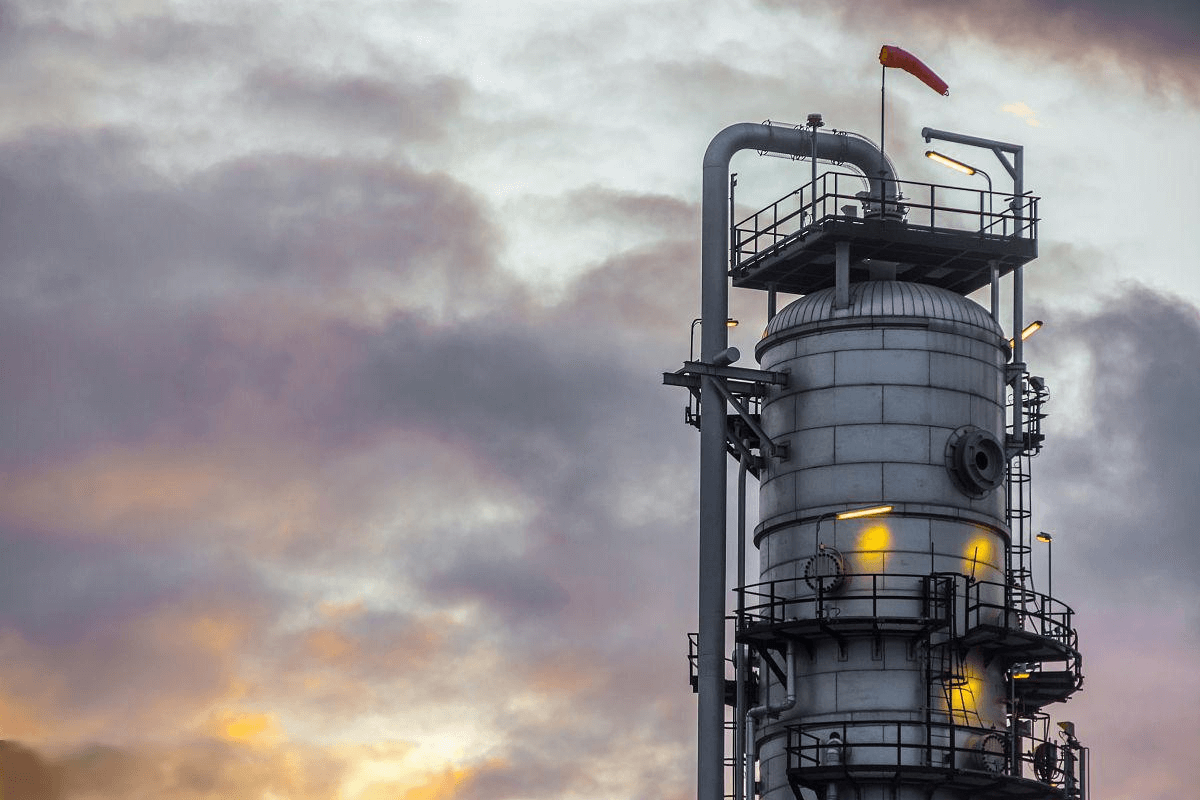

When the pipeline medium is high-temperature, it imposes stricter requirements on the sealing surfaces of valve seats, gaskets, packing, and other sealing materials. These materials need to withstand the corresponding high-temperature environment while maintaining normal sealing functions. Therefore, it is necessary to select sealing materials with good thermal stability for material selection. At the same time, the impact of high-temperature media on non-metallic components within the actuator and operating personnel must be considered to ensure that handles, handwheels, or other operating mechanisms can function normally in the current environment.

Specially crafted gate valves, globe valves, check valves, and ball valves, along with the addition of heat dissipation devices, can prevent the oxidation of gaskets and packing materials or the damage to non-metallic components in the actuator under high-temperature operating conditions, ensuring the normal operation of the valves in the current working environment.

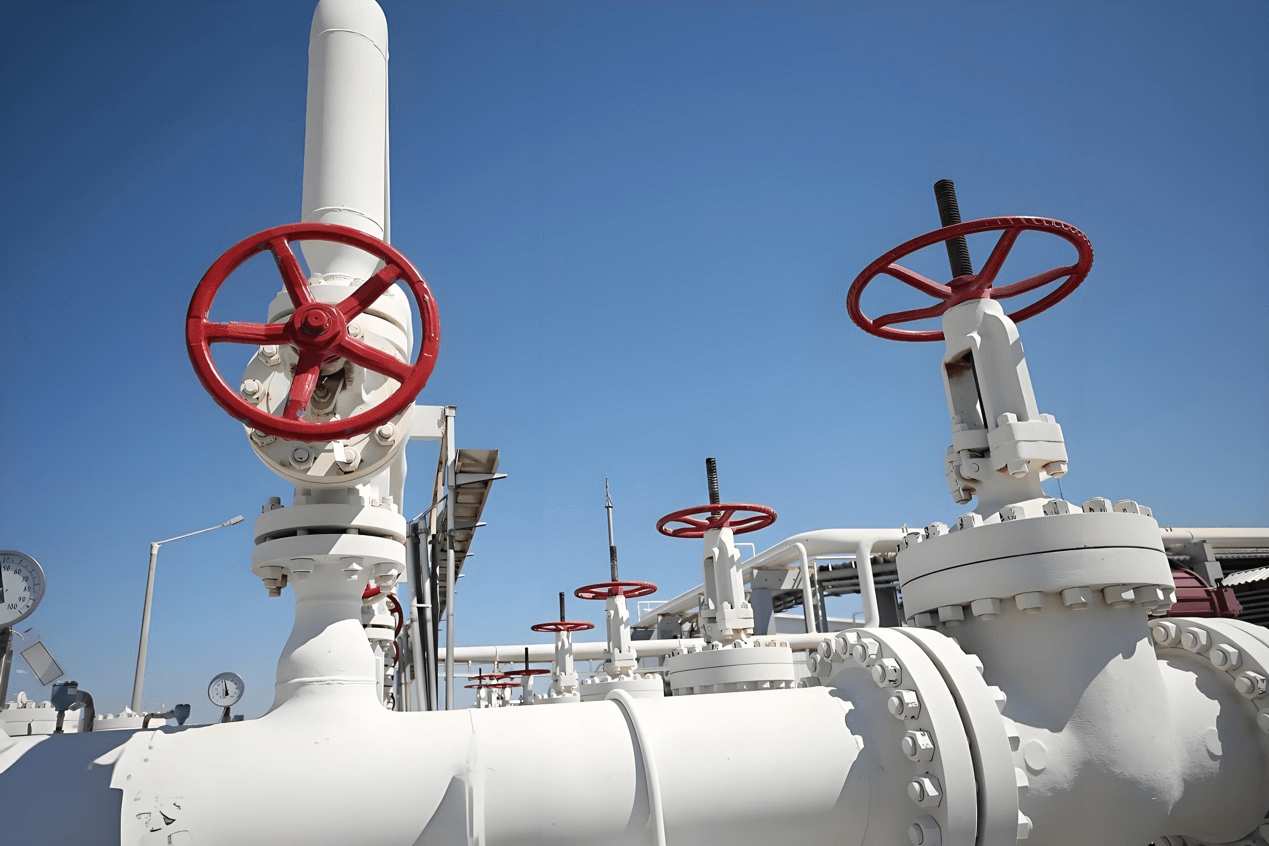

Newly extracted oil and natural gas often contain small amounts of mixed gases such as H2S, which can corrode valve and pipeline materials in humid environments, posing significant safety hazards. The common types of corrosion are stress cracking or hydrogen induced cracking.

Ball valves crafted from special corrosion-resistant materials and high-performance sealing materials are capable of withstanding the erosive effects of acidic media. They maintain superior sealing performance even in acidic environments, ensuring zero leakage or an extremely low leakage rate when the valve is closed. This ensures the long-term stable operation of the valve in acidic conditions.

The newly extracted oil and natural gas from underground oil wells often contain hard particles such as sand, which are not only prone to wearing or scouring the sealing surface and internal cavity of the valve, but may also accumulate in the middle chamber, affecting the opening and closing of the valve.

The ball valve consists of a spherical valve core and a fixed valve seat, without complicated internal structures or flow passages. This simplistic design makes it less prone to clogging by particles, thereby reducing the risk of particle accumulation and blockage. Additionally, the valve core material possesses high wear resistance, effectively withstanding the abrasion caused by particles on both the valve core and seat.

Flour Valve

Via Fausto Coppi, 5

23879 Verderio Inferiore (LC)

Website : www.flv-valve.com

E-mail : info@flv-valve.com